OUR PRODUCTS

Fluxrite System

The Fluxrite Belt Demagnetisation System is the first permanently installed belt demagnetisation system for steel cord belt.

The metal detectors on conveyor belts with steel cords will have a reduced effectiveness if those cords have residual magnetism. The magnetism can cause the conveyor to false trip when there is nothing on the belt or the tramp metal can pass through undetected due to reduced sensitivity to stop false trip from occurring.

Why do steel belts become magnetised?

The steel cords within the belt can become magnetised by Tramp Metal Magnets, cord scanning equipment or from large electrical currents from drive motors.

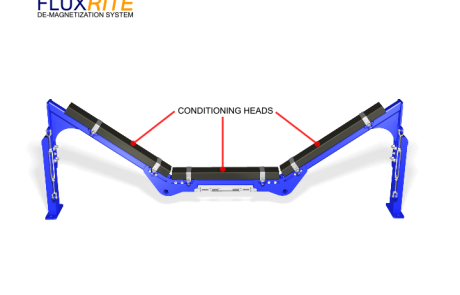

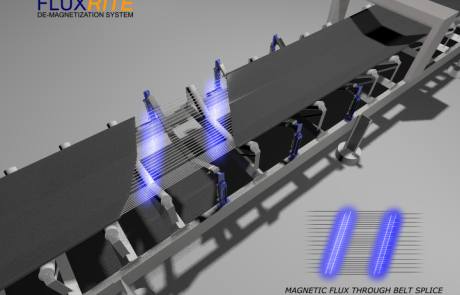

HOW DOES IT WORK?

The belt demagnetisation system is designed to reduce strong pockets of magnetic flux that occur in the splices of steel cord conveyor belts. The system comprises of several conditioning heads placed below the carry side of the belt that normalises, then attenuates the magnetic flux. As the magnetised splices pass over the system the demagnetising process takes place reducing the magnetic flux by 95%

WHY DO STEEL CORD BELTS BECOME MAGNETISED?

The steel cords within the belt can become magnetised by Tramp Metal Magnets, cord scanning equipment or from large electrical currents from drive motors.

PULLEYS

ROLLERS

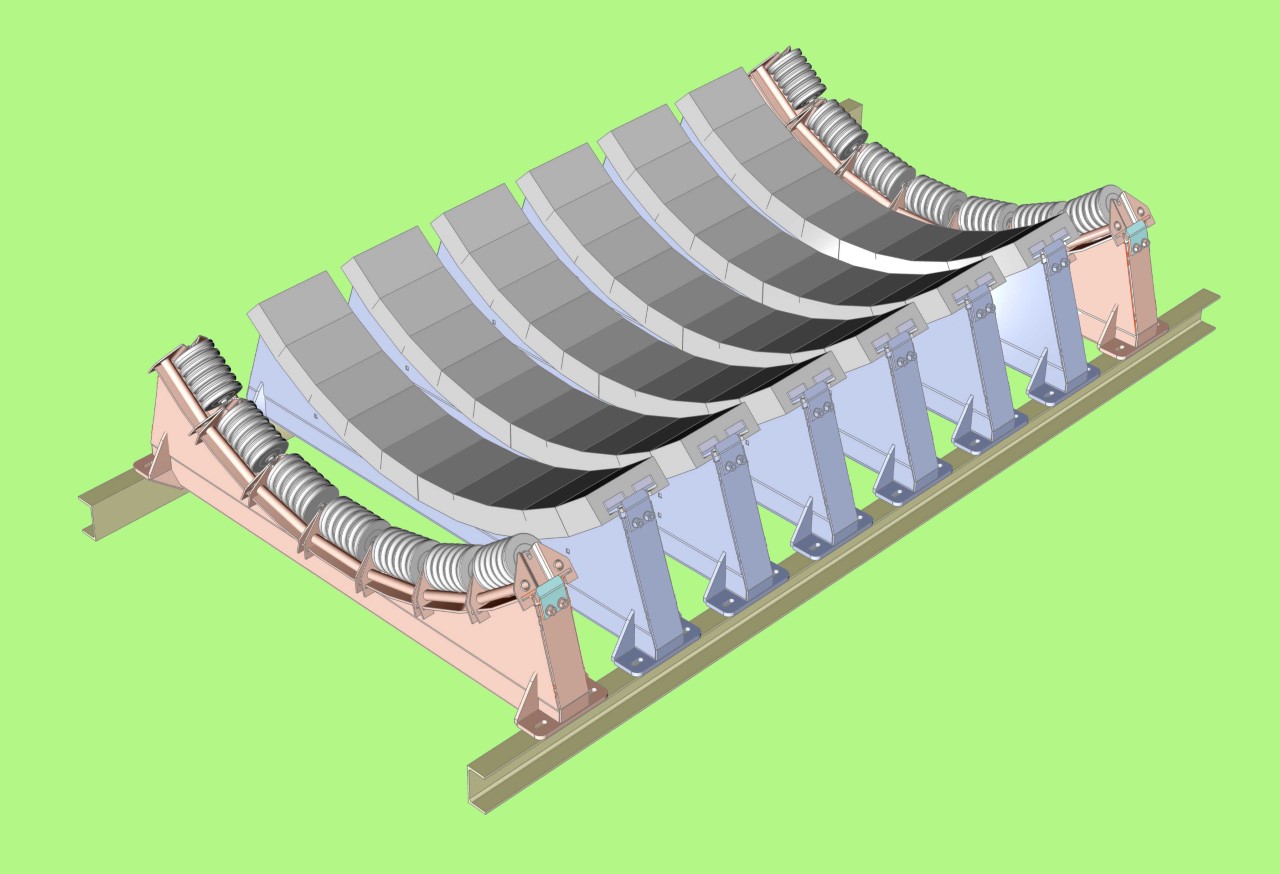

Veycon VOS design and manufacture “heavy duty” idlers and rollers for impact zones and heavy tension areas where high failure rates occur. These idlers and rollers have design and engineered bearing housings and shafts complete with SKF seals and bearings to give performance and longevity. Impact idlers have autoclaved natural or FRAS rubber with soft design edges and are cylindrically ground to guarantee smooth and balanced operation with the integrity of the rubber. The result is improved wear life and performance reducing down-time due to idler and roller failures

Our ultra-heavy duty forming rollers are CNC machined from AS1442 1045 grade billet steel for the shells and AS1444 grade 4140 for the shafts. Our rollers are assembled using SKF bearings and a unique sealing method to eliminate moisture and contaminate ingress.

IDLERS

Veycon VOS Rubber Disc Return Idlers are manufactured with durable natural, or FRAS rubber discs positioned at regular intervals along the roller to effectively eliminate conveyor belt carry back build up. This is done by breaking up the material on the return side of the conveyor belt which is normally concentrated in the centre of the belt. The rubber discs are bunched together at either end of the roller to provide support and protection to the belt edges.

CALL US

0409 030 069

EMAIL US

bob@veycon.com.au

CALL US

0409 030 069

EMAIL US